Traditionally the attendance at an establishment is usually done in a book register. It is time consuming. It is very difficult to verify the attendance over long periods. This method is very time consuming and very difficult to verify the attendance over a week or above. Keeping attendance registers is space consuming. Here chances of doing malpractice in marking attendance are high.

RFID based attendance system uses RFID tags for each person. A person marks the attendance by swiping the tag near RFID reader module. The attendance is temporarily saved in the EEPROM. At any time the circuit can be connected to a computer and the attendance is moved from EEPROM to a text file in computer. It has following advantages. (1) Simplicity and reliability, (2) Saving attendance in a computer allows easy verification and longer record keeping.

It works on radio frequency transmitters and receivers. Each person is given a RF ID card which is having a unique code. When it is swiped on a RF ID card reader, it reads the code and is stored. The attendance is temporarily saved in the EEPROM. At any time the circuit can be connected to a computer and the attendance is moved from EEPROM to a text file in computer. The advantage of this system is simplicity and reliability. Saving attendance in a computer allows easy verification and longer record keeping.

The DT125R series RFID Proximity OEM Reader Module has a built-in antenna in minimized form factor. It is designed to work on the industry standard carrier frequency of 125 kHz. This LF reader module with an internal or an external antenna facilitates communication with Read-Only transponders type UNIQUE or TK5530 via the air interface. The tag data is sent to the host systems via the wired communication interface with a protocol selected from the module pinout. The LF DT125R module is best suited for applications in Access Control, Time and Attendance, Asset Management, Handheld Readers, Immobilizers, and other RFID enabled applications.The AUTOMATIC DATA COLLECTION Technology used in th RFID reader.

WORKING

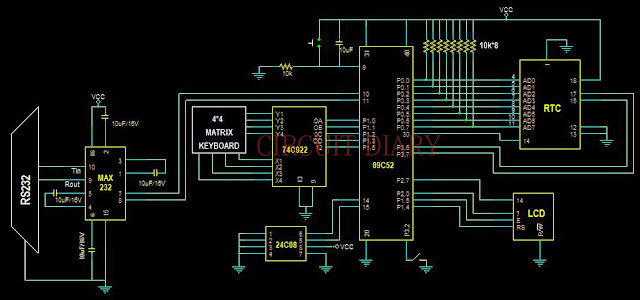

Microcontroller reads time from real time chip DS12887. Whenever a RFID tag is brought near RFID module, it sends the card number in ASCII fomat to the microcontroller. The microcontroller compares this number with those numbers in the EEPROM. If match is found, it first check whether it is a master card, then it displays menu for master card. If not, it displays the ID number and then sends the time and date details along with ID number to EEPROM for marking daily attendance. If no matches found, the microcontroller displays ‘Card Not Programmed’ in LCD.

Master card menu consists of set time, add, edit, delete, transfer. The various options are selected using the keypad keys- up, down, enter, cancel. Keypad encoder converts the key pressed into corresponding hex file. The output from RFID is given as the serial input. The card ID number is 8 bytes long and two extra bytes serve as start and stop bits.

Set time: It is used to edit the time of RTC. The time is entered using the keypad.

Add: It is used to add a new tag and store the new tag number and ID number to EEPROM.

Edit: It is used to edit the card ID number. The new ID number is entered through keypad.

Delete: It is used to delete a card from record.

Transfer: This option is used to transfer the marked attendance stored in EEPROM to the computer.

MAX232 is used to convert the TTL voltage to RS232 compatible voltage. Real time clock is used to provide the date, month, and year details for marking the attendance.

Almost all electronic devices used in electronic circuits need a dc source of power supply to operate .The source of dc power is used to establish the dc operating points for the passive and active electronic devices incorporated in the system. The combination of a transformer, a rectifier, and a filter constitutes an ordinary dc supply, also called an unregulated power supply. For many applications in electronics unregulated power supply is not good because of the following reasons.

· Poor regulation.

· Variations in the ac supply main.

· Variations in temperature.

Download full Report with Source code

10:53 AM

10:53 AM

• » νιηєєтн νєηυgσραℓ « •

• » νιηєєтн νєηυgσραℓ « •

4 comments:

Please give me full report with source code ..

pls give me full details and source code of this project

good article .thanks for sharing...........

http://finalsemeceprojects.blogspot.in/

Nice post your blog

rfid reader

Post a Comment